OS&D Guide | Prevent Freight Damage & Shortage Denver

OS&D Guide: Overage, Shortage & Damage—Your Playbook for Smarter Freight Claims and Preventing Logistics Mishaps

The Lowdown on OS&D

Businesses across the Colorado Front Range are losing serious cash every year to OS&D—that's overage, shortage, and damage—in their freight shipments. It's a real drag on supply chain efficiency and eats into your profits. This guide is your cheat sheet to understanding why OS&D is a big deal, how to get ahead of it, what to do when freight gets damaged, and how Denver Express Co.'s logistics know-how can keep your goods safe and sound. You'll get the scoop on what overage, shortage, and damage actually mean, the best ways to pack, load, and use tech to prevent issues, how to nail the claims process, and the smart move of teaming up with a local 3PL.

What's the Deal with OS&D in Logistics and Why Should You Care?

OS&D is all about when what you shipped doesn't match what arrived—you got too much (overage), too little (shortage), or it showed up busted (damage). Catching and fixing these hiccups keeps your inventory on the up-and-up, stops money from vanishing, and keeps your customers happy. It's the bedrock of a supply chain that can roll with the punches. Solid OS&D management means better order fulfillment and tighter cost control, paving the way for smart prevention tactics.

What Exactly Is OS&D in Logistics?

OS&D, short for Overage, Shortage, and Damage, points to mismatches in freight shipments. These slip-ups can drain your revenue, jack up costs, and leave customers fuming, so having a system to track and manage them is key.

SCM EDU, What is Over, Short, and damaged (OS&D) in logistics? [2024]

This source lays out what OS&D is and how it hits businesses, which is super helpful for getting the gist of this article.

Decoding OS&D: What Overage, Shortage, and Damage Really Mean

OS&D is your shorthand for Overage, Shortage, and Damage—the three main freight screw-ups that every logistics crew needs to keep tabs on and sort out.

| The Glitch | What It Is | How It Messes Things Up |

|---|---|---|

| Overage | Getting more stuff than your shipping papers say you should | Messes up your stock counts and can lead to paying for storage you don't need |

| Shortage | Getting less stuff than what's listed on the bill of lading | Means backorders, lost sales, and paying extra for rush shipping |

| Damage | Goods getting dinged up during their journey or while being handled | Leads to writing off inventory, customer returns, and a headache of claim paperwork |

Each of these issues throws your inventory accuracy and profits out of whack, so let's dive into how overages sneak in and mess with your warehouse counts.

How Do Overages Happen and What's Their Impact on Your Inventory?

Overages usually pop up because of sloppy counting at the start, human error when entering data, or packaging that's just not quite right.

- When labels are wrong or pallet counts are off at the shipping dock, you end up with surprise extras when things arrive.

- If you're scanning loose items without double-checking, your inventory numbers get inflated, leading to stock imbalances.

- Skipping or doing weak cycle counts means you won't catch those surplus items until it's time for a full reconciliation, leaving your records inaccurate for longer.

Sticking to proper counting rules and using barcode scanners can zap most overage issues, giving you a clear view of your inventory in real-time and ensuring orders go out right.

What Causes Shortages and How Do You Spot Them?

Shortages happen when items go missing, get picked wrong, or aren't logged correctly during transit.

- Packing Slip-Ups: Items get left behind because of picking errors or the wrong SKU being grabbed.

- Lost in Transit: Stuff gets stolen or misplaced during the journey, especially on multi-stop routes.

- Data Black Holes: Not scanning inbound shipments right away means you miss spotting shortages quickly.

Regularly comparing your purchase orders, bills of lading, and warehouse records will catch shortages before they hit your customers, keeping your order accuracy solid.

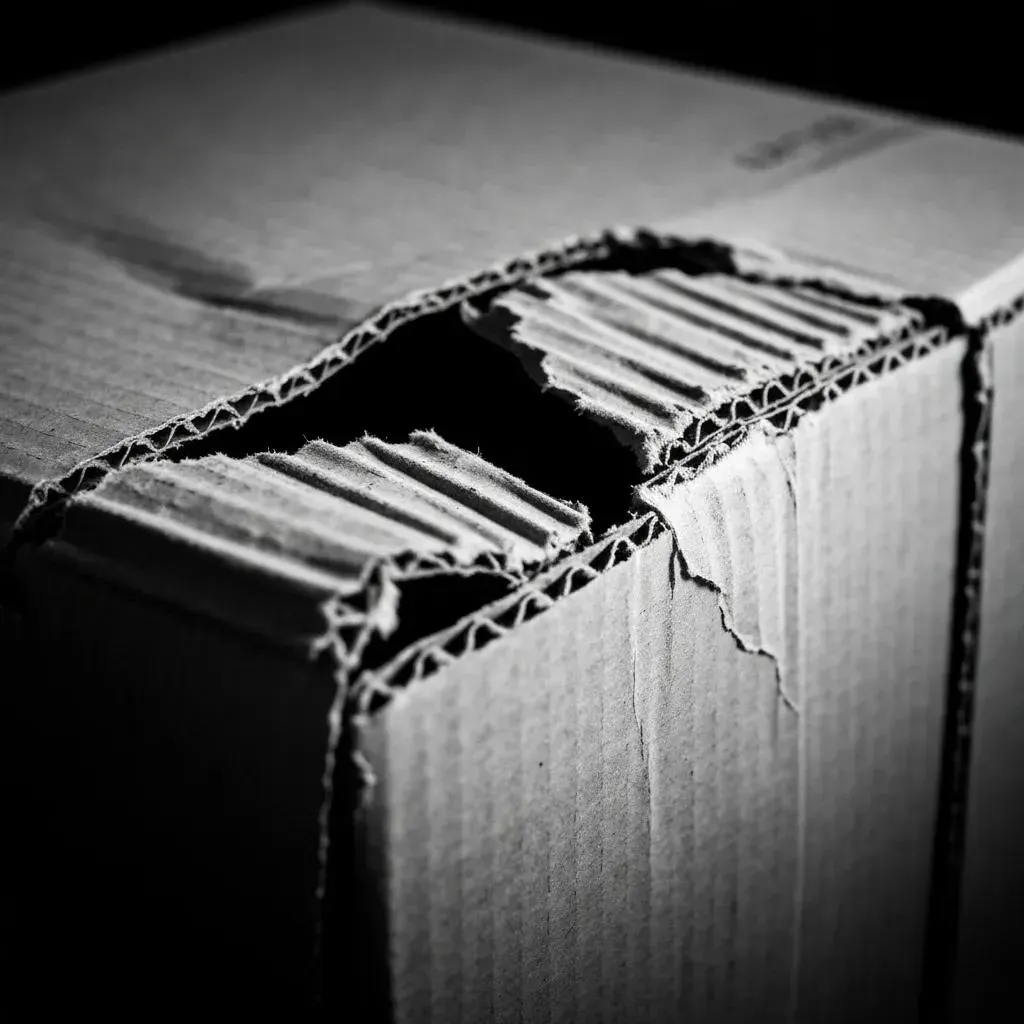

What Kind of Freight Damage is Common on the Road?

Freight damage during transit or storage can stem from mechanical issues, the environment, or rough handling:

- Impact Damage: Caused by sudden bumps or drops when loading and unloading.

- Compression Damage: Happens when stacked pallets are too heavy, squashing the boxes underneath.

- Moisture and Corrosion: From packaging that doesn't hold up in damp or wet conditions.

- Temperature Swings: Affecting goods that need precise temperature control, like food or meds.

Pinpointing these damage types helps you fine-tune your packaging to cut down on claims and spoiled goods.

Why OS&D is a Game-Changer for Supply Chain Smoothness and Cost Savings?

OS&D incidents add to your logistics bill through extra handling, reshipments, and administrative headaches. Getting OS&D sorted out precisely means accurate inventory values, smarter use of warehouse space, and avoiding those costly emergency airfreight runs. Smart discrepancy management also keeps your suppliers and carriers on their toes, driving constant improvements and cutting costs across your entire supply chain.

OS&D and Its Ripple Effect on Logistics

OS&D headaches can lead to operational snags like processing delays, delivery hiccups, and wonky inventory numbers. Businesses can actually save money by tackling OS&D head-on, making the supply chain more profitable and efficient.

GoComet, Addressing OS&D In Logistics For Improved Operations [2024]

This source dives into how OS&D impacts logistics operations, which totally backs up why this article is stressing the importance of managing it.

Your Go-To Guide for Preventing Overage, Shortage, and Damage

Stopping OS&D before it starts means having solid packaging rules, sharp inventory systems, well-trained crews, and cutting-edge tracking tech. When you weave these together, you build a strong defense against risks and keep your products in top shape from start to finish.

How Does Smart Packaging and Loading Slash OS&D Risks?

Good packaging and loading practices not only protect your goods but also keep your counts accurate:

- Consistent Carton Sizes mean pallets stack neatly, preventing slides and impacts.

- Protective Fillers like airbags, corner protectors, and shrink wrap cushion against bumps and keep loads steady.

- Smart Loading Plans distribute weight evenly, avoiding crushing damage and collapsing pallets.

Uniform packaging and strategic pallet loading directly cut down on damage and ensure you have the right number of items, setting the stage for tech-driven controls.

How Do Warehouse Management Systems (WMS) Boost Inventory Accuracy?

Warehouse Management Systems (WMS) automate the whole process—receiving, putting away, picking, and cycle counts—slashing manual errors and giving you a real-time view of your stock.

- Barcode and RFID Scanning instantly logs every move, cutting down on data entry blunders.

- Automated Alerts for quantity mismatches flag issues for immediate investigation.

- Scheduled Cycle Counts keep your inventory accurate ongoing without shutting down operations.

WMS: Your Secret Weapon for Inventory Accuracy

Warehouse Management Systems (WMS) are crucial for boosting inventory accuracy by automating tasks, providing live tracking, and optimizing space. WMS leverages tech like barcodes and RFID tags for unmatched visibility into stock levels and item locations.

VGS Software, How Does a WMS Improve Inventory Accuracy? [n.d.]

This source breaks down how Warehouse Management Systems (WMS) sharpen inventory accuracy, which is spot-on for what this article is talking about regarding inventory management.

A modern WMS plays nice with transportation management and enterprise resource planning systems, ensuring OS&D prevention is smooth sailing across all your operations.

What Employee Training and Quality Checks Can Minimize OS&D?

A well-trained team sticks to standard operating procedures that prevent errors:

- Receiving Workshops teach accurate unloading counts and how to spot damage.

- Picking Certification Programs ensure items are picked and scanned correctly every time.

- Quality Audits randomly check shipments to make sure packaging and counting standards are being met.

Ongoing training and clear quality control guidelines build a culture of responsibility that stops OS&D issues before they even start.

How Can Tech Like IoT and Tracking Systems Help Prevent OS&D?

Tying in IoT sensors and GPS tracking gives you a clearer picture of where your shipments are and what conditions they're in:

| The Tech | What It Does | The Upside |

|---|---|---|

| GPS Telematics | Keeps an eye on vehicle routes and stops | Flags unauthorized delays or detours |

| Temperature Sensors | Monitors the surrounding air | Protects temperature-sensitive items from spoiling |

| Shock and Tilt Monitors | Records impacts or tipping | Alerts teams to potential handling damage |

| Cloud-Based Dashboards | Provides real-time insights | Helps spot emerging OS&D trends for quick action |

Rolling out these technologies allows for predictive analysis and fast responses to in-transit problems, ultimately preventing shipment discrepancies.

Mastering the Freight Damage Claims Process Like a Pro

A slick freight damage claims process means getting your documentation done fast, talking clearly with carriers, and gathering all your evidence to get paid quickly.

What Are the First Moves for Documenting and Reporting Freight Damage?

Start your claims with quick, detailed records:

- Snap photos of all visible damage as soon as it arrives, before you even unpack.

- Make a note of any discrepancies right on the Bill of Lading.

- Shoot a written notice to the carrier’s claims department within 24 hours.

Top Tips for Freight Claims

Documenting damage, holding onto everything, asking the carrier to inspect, providing all the paperwork, and paying the freight bill are all crucial steps for freight claims. Snapping pics of damaged packages and noting issues on the delivery receipt are also must-dos.

Falvey Insurance Group, 5 Best Freight Claims Practices [2018]

This source dishes out the best practices for freight claims, which is totally in line with what this article is covering about navigating the damage claims process.

These initial steps kick off the claim clock and build the factual foundation you need to get things resolved.

How Is Carrier Responsibility Figured Out in Freight Damage Claims?

Carrier liability comes down to figuring out if the damage happened while the shipment was in their care and if they dropped the ball on proper handling. Factors include what your contract says, the declared value, and whether packaging standards were followed. Knowing the carrier's liability limits under the relevant rules helps you set realistic expectations and negotiate effectively.

What Key Info Do You Need to File a Freight Claim?

To make your claims stick, you need solid paperwork:

- Bill of Lading: Shows shipment details and that the carrier accepted it.

- Proof of Delivery (POD): Confirms the delivery date and any condition notes made.

- Damage Photos: With timestamps and clear labels showing what's damaged.

- Packing Lists and Invoices: To prove the value and quantity of what was shipped.

Submitting all your documents upfront speeds up how quickly claims get reviewed and approved.

How Does Denver Express Co. Help You Through the Claims Maze?

Denver Express Co. steps in as your champion, working directly with carriers to handle claim submissions, chase down updates, and negotiate settlements. Our team gathers all the proof, hits all the filing deadlines, and keeps you in the loop with regular progress reports. This hands-on support frees you from the admin burden and speeds up getting your money back.

Tackling Overage and Shortage Discrepancies Like a Pro

Sorting out overages and shortages fast means using systematic reconciliation, being upfront with reporting, and having clear procedures for adjusting inventory.

How to Pinpoint and Reconcile Overages in Your Inventory?

Efficient reconciliation involves:

- Comparing Received Counts against your purchase orders and packing slips.

- Flagging Discrepancies in your WMS as overage events for review.

- Documenting How You Fixed It, whether that's sending back extras or reallocating stock.

Consistent processes ensure overages are corrected and your stock records are updated right away.

What Are the Best Ways to Investigate and Report Shortages?

Digging into shortage issues follows these steps:

- Check Carrier POD and Seals for any signs of tampering.

- Review Warehouse Logs to trace every step of inbound handling.

- Do a Root-Cause Analysis to figure out if errors happened at the start, during transit, or upon receiving.

Reporting your findings with clear evidence allows for corrective actions and stops the problem from happening again.

How to Use Proof of Delivery and Shipping Docs in OS&D Cases?

Proof of Delivery (POD), Bills of Lading, and packing lists are the backbone of any OS&D case. Always:

- Match Documented Quantities with what you physically count upon receipt.

- Get Signed Condition Notes on the POD if there are any signs of damage or shortages.

- Keep the Original Paperwork handy for carrier audits and claim appeals.

Accurate shipping documents create an undeniable chain of custody that strengthens your claims and reconciliation efforts.

How to Handle Backorders and Inventory Adjustments After Shortages?

Once you've identified a shortage:

- Set Up Backorders in your WMS with clear priority levels.

- Let Customers Know About New Delivery Dates proactively.

- Adjust Your Inventory Buffers or reorder points to prevent future stock-outs.

A structured backorder process keeps customers happy and gets you back to on-time fulfillment.

Why Team Up with Denver Express Co. for OS&D Management in the Colorado Front Range?

As your local logistics partner, Denver Express Co. brings hyper-local insights, end-to-end visibility, and dedicated OS&D prevention and resolution services designed specifically for Colorado businesses.

What OS&D Prevention and Resolution Services Does Denver Express Co. Offer?

- Custom Packaging Solutions built to handle the unique climate and handling conditions of the region

- Real-Time WMS Integration that sends instant alerts for quantity mismatches

- Claims Advocacy with direct carrier communication and help to speed up settlements

- Dedicated OS&D Reporting Dashboards for crystal-clear incident tracking

What Denver Express Brings to the Table

Denver Express is your go-to for cross-docking and warehousing in Colorado's Front Range, offering services like cross-dock capabilities, LTL services, and hot shot services. Our mission is to deliver top-notch customer service with fast and effective results.

Denver Express, Additional Logistics & Transportation Services [n.d.]

This source gives you the lowdown on Denver Express's services, which is super relevant to how we can help you with OS&D management.

How Does Denver Express Co.’s Local Know-How Benefit Colorado Businesses?

We've got a deep understanding of Front Range transportation routes, how seasonal weather plays a role, and state regulations, so we can anticipate risks specific to this area. This local insight means our packaging and routing strategies are perfectly tuned for shipments heading to Denver, Colorado Springs, and the mountain corridors.

What Are the Perks of Having End-to-End Supply Chain Visibility with Denver Express Co.?

Full visibility—from the moment we pick up to the final drop-off—lets us catch and prevent OS&D issues before they escalate. Our clients get access to dashboards showing live shipment status, alerts from temperature and shock sensors, and inventory counts, empowering them to make smart, data-driven decisions that reduce the capital tied up in excess or missing stock.

How Have Colorado Businesses Cut OS&D Costs by Partnering with Denver Express Co.?

One Denver-area retailer slashed its claims administration costs by 40% thanks to our automated documentation workflows and on-site receiving procedures. A local food distributor reduced spoilage-related damages by 25% by using our climate-controlled storage and IoT monitoring, proving that targeted OS&D solutions lead to real savings.

Got Questions About OS&D and Freight Claims? We've Got Answers.

Logistics teams often need clarification on OS&D terms, how claims work, and what to do to prevent issues. The most common questions revolve around understanding the basic terms, handling damage claims smoothly, and keeping inventory tight to avoid future discrepancies.

What Does OS&D Mean in Logistics?

OS&D, or Overage, Shortage, and Damage, refers to the main freight discrepancies where shipped quantities don't match orders or goods arrive damaged. Using the right terms ensures consistent reporting and resolution across carriers and warehouses.

How Do You Handle Freight Damage Claims Step-by-Step?

Start by documenting damage immediately, notify the carrier with photo evidence and signed delivery notes, gather all shipping documents, submit a formal claim with all evidence within the carrier's deadlines, and follow up until it's settled. This structured approach minimizes delays and lost compensation.

How Can I Prevent Overage and Shortage in My Warehouse?

Put in place a solid warehouse management system with barcode or RFID scanning, enforce strict receiving protocols including two-point verification, conduct regular cycle counts, and train employees on standardized handling procedures. These steps ensure reliable inventory accuracy from the dock to the shelf.

What Documentation Is Required for Filing a Freight Claim?

Essential documents include the original Bill of Lading, signed Proof of Delivery noting any condition discrepancies, packing lists, commercial invoices, and photographic evidence. Complete and accurate paperwork speeds up the carrier's investigation and claim approval.

How Long Does the Freight Claims Process Usually Take?

Most carriers wrap up claims within 30 to 45 days of submission, though complex investigations involving third-party audits can stretch to 60 or 90 days. Staying on top of it and having all your documentation in order can often speed things up.

How Does OS&D Impact Costs and Supply Chain Sustainability?

OS&D incidents drive up operational expenses and hurt sustainable logistics by creating more waste, extra handling, and emergency shipments. Effectively managing these discrepancies is key to building a leaner, greener supply chain.

What's the Financial Hit of OS&D for Businesses?

Industry figures show that OS&D can eat up 5–10% of logistics budgets through direct losses, claim administration, and corrective actions. Even a small reduction in discrepancies can mean significant savings on your bottom line.

How Has E-commerce Growth Made OS&D Challenges Worse?

The explosion in parcel volumes, the many hands shipments pass through, and the varied packaging standards in e-commerce create more opportunities for shortages, damages, and miscounts. Fast-moving inventory flows demand flexible OS&D processes to keep up with customer expectations for speed and accuracy.

How Do Sustainable Packaging and Logistics Practices Cut Down on Damage?

Eco-friendly materials like recycled corrugated board and modular protective inserts absorb impacts while reducing waste. Optimized pallet configurations and reusable plastic containers cut down on single-use packaging, lowering both OS&D incidents and environmental impact.

How Do Labor Shortages Affect OS&D Incidents?

Staffing gaps and high turnover in warehouses and transportation can lead to rushed handling, data entry errors, and skipped inspections, all of which increase OS&D. Partnering with an experienced logistics provider ensures a consistent supply of skilled labor and unwavering adherence to best practices.

Every OS&D event is a chance to improve your processes, from packaging standards to advanced monitoring and claims advocacy. By integrating these prevention strategies, documentation workflows, and local logistics expertise, businesses in the Colorado Front Range can turn discrepancy challenges into opportunities for efficiency, sustainability, and cost savings.

Teaming up with a trusted provider means that inventory accuracy, claims resolution, and proactive risk management become your strengths, not recurring headaches. With the right systems, training, and regional insight, you can eliminate costly freight discrepancies and build a resilient supply chain that fuels growth and customer satisfaction.