Accessorial Charges in Freight: Detention, Layover, Lumper Fees, and TONU (and How to Control Them)

Accessorial charges are the “extra line items” that show up when a shipment needs something beyond standard pickup and delivery—or when time, information, or facility constraints create delays. This guide focuses on the four that most often surprise shippers and brokers: detention, layover, lumper fees, and TONU. Pricing and rules vary by carrier, facility, and contract, but the decision framework below helps you forecast risk and reduce surprises.

If you’re trying to keep freight costs predictable, start with your base service plan first. Then use the checklists and audit steps here to prevent avoidable fees.

What are accessorial charges, and why do they show up after you’ve quoted a load?

Accessorial charges are additional fees for services or situations outside the “standard” shipment—often triggered by wait time, special handling, or last-minute changes. They typically appear after quoting because many are reactive: the fee is only known once the driver arrives, the facility’s constraints are confirmed, or the load is canceled late.

In practice, accessorial are how carriers recover costs when the shipment requires extra time, labor, equipment, or coordination that wasn’t priced into the linehaul.

Which accessorial charges cause the most surprises (detention, layover, lumper, TONU)?

The biggest surprises come from fees tied to time and labor—especially when responsibilities aren’t clearly agreed to before tender.

| Charge | What triggers it (plain-English) | How it’s typically billed | Who can influence it most | What proof usually matters |

|---|---|---|---|---|

| Detention | The driver waits longer than the facility’s allowed free time to get loaded or unloaded | Time-based (hourly or increments) | Shipper/receiver plus broker or dispatcher | Check-in and check-out times, appointment confirmation, driver notes, facility logs |

| Layover | Loading or unloading can’t be completed the scheduled day and the driver loses a working day | Day-based (per day or night) | Shipper/receiver plus broker or dispatcher | Rescheduled appointment, refusal notes, arrival attempts, communications trail |

| Lumper fee | A facility requires paid labor to unload or load, often by a third party | Pass-through (receipt-based) or facility-set fee | Receiver or facility (policy-driven) | Lumper receipt, payment record, delivery paperwork |

| TONU (Truck Ordered Not Used) | The truck is booked or committed and the load is canceled late or isn’t ready | Flat event fee (varies by agreement) | Shipper or broker (tender quality and cancellation timing) | Rate confirmation, dispatch or arrival evidence, cancellation timestamp |

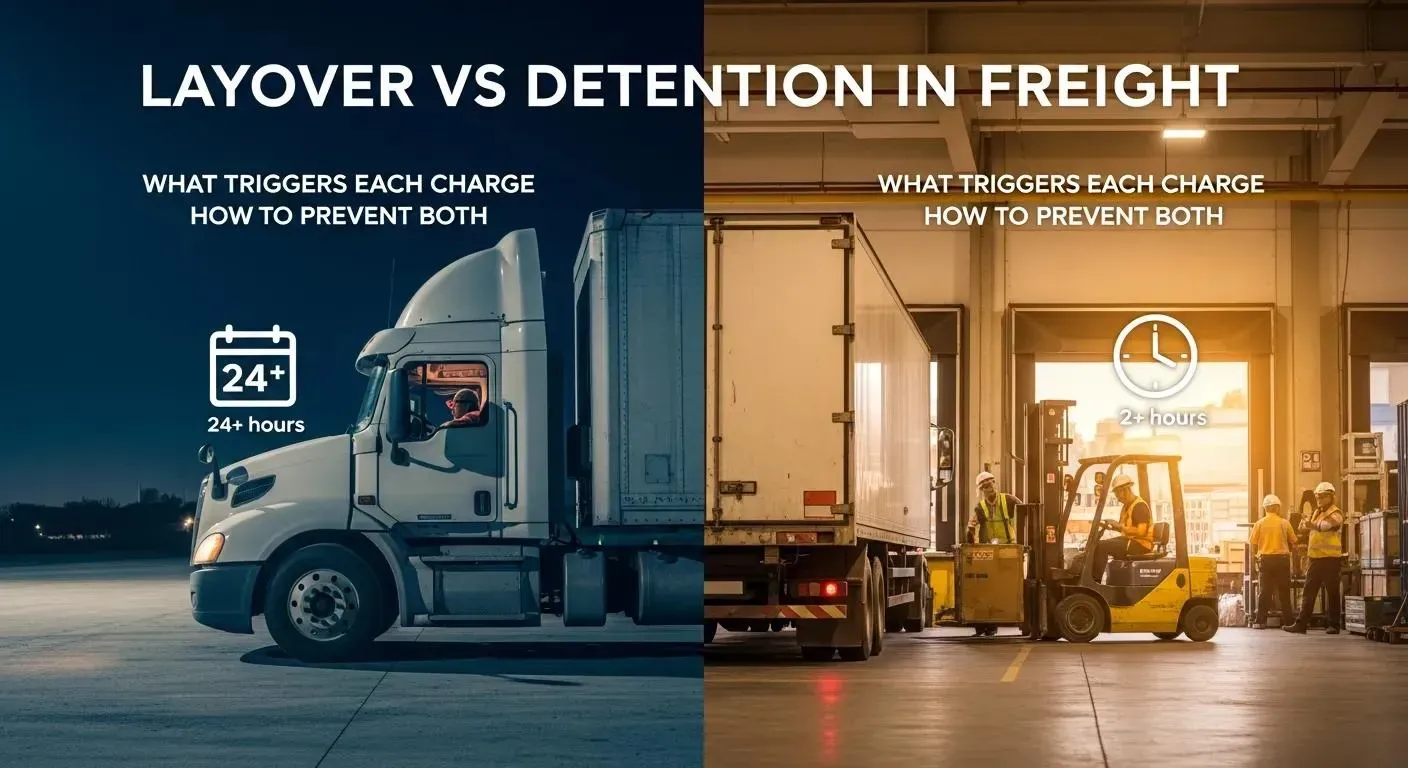

What is detention in trucking (and what it’s not)?

Detention is paid waiting time at pickup or delivery when the driver is ready and the shipment isn’t processed within the agreed window. It’s not the same as a layover—detention is usually about hours, while layover is about losing a day.

What is a layover charge?

A layover charge usually applies when a truck can’t load or unload on the scheduled day, forcing the driver to stay overnight or lose a working day. It often happens after missed appointments, freight not being ready, facility congestion, or equipment issues.

What is a lumper fee, and why does it happen?

A lumper fee is charged when a facility requires paid labor to load or unload. Many facilities don’t want drivers unloading freight themselves, or they mandate specific third-party labor.

What is TONU, and when does it apply?

TONU (Truck Ordered Not Used) is a cancellation-related fee used when a carrier committed capacity and then the load was canceled too late to replace it. Whether a TONU applies (and how much) depends on the agreement and timing.

How are these fees typically calculated, and what documents prove they’re valid?

Most accessorial fall into three billing patterns: time-based, day-based, or receipt-based pass-through. Your job is to make the trigger conditions measurable so you can approve or dispute charges quickly.

Common proof that reduces disputes:

- Appointment confirmations (including time windows and any “first-come/first-served” language)

- Driver check-in/check-out timestamps (texts, ELD notes, facility gate logs)

- BOLs and PODs (with exception notes if something went wrong)

- Facility communications (emails/texts showing delays, reschedules, or refusal)

- Receipts for any pass-through labor charges (especially lumpers)

External references (definitions / terminology):

- CSCMP glossary (industry definitions)

- FHWA freight glossary (general freight terminology)

- Library of Congress trucking definitions (quick reference)

What’s the simplest checklist to reduce accessorial risk before you tender a load?

The fastest way to reduce accessorial surprises is to make the “unknowns” explicit before the truck is dispatched.

Pre-tender accessorial checklist

- Confirm appointment type: scheduled window vs FCFS; any cutoff times

- Confirm facility policy: lumper required? driver unload allowed? payment method required?

- Confirm freight readiness: product staged, counts verified, labels correct, load bars/straps if needed

- Confirm documentation: correct BOL, PO numbers, delivery instructions, contact names

- Confirm equipment match: trailer type, pallet type requirements, any special handling

- Confirm who approves accessorials (name + method) and what proof is required

- Confirm plan B if the facility can’t receive today (staging, rework, reschedule path)

How do you reduce accessorial charges without slowing down the shipment?

You reduce accessorial by removing the two main causes: unplanned wait time and unplanned labor.

Start by tightening appointment discipline (clear windows, correct facility contacts, readiness checks). Next, use operational alternatives when the receiver can’t take freight today—short staging or cross-docking can be cheaper than a full day of disruption.

If you frequently run into receiver congestion, consider planning a controlled transfer step (cross-dock) so the linehaul truck isn’t trapped at a facility waiting on doors.

What do accessorials look like in real operations? (two mini-scenarios)

In real life, accessorial rarely happen “because the carrier wanted extra money.” They happen because the plan didn’t match facility reality.

Scenario 1: Detention + lumper surprise at a retail DC

A broker tenders a dry van load to a busy retail DC. The appointment was booked, but the receiving notes didn’t mention that the DC requires lumpers and only accepts specific payment methods. The driver arrives, waits for a door, and then must pay a lumper service to unload. The shipment ends with two add-ons: detention for the wait time and a lumper pass-through.

What would have prevented it: confirming lumper policy + payment method during appointment scheduling, and capturing the approved proof requirements in writing.

Scenario 2: TONU after a “ready by 2 PM” pickup that wasn’t ready

A shipper says the load will be ready by 2 PM. The carrier commits a truck and dispatches. At the pickup, the product isn’t staged and the shipper needs “another few hours.” The carrier can’t hold indefinitely without losing the rest of the day’s revenue. The load is canceled and the carrier invoices a TONU per the rate confirmation.

What would have prevented it: a stricter readiness check (counts, staging confirmation) and a clear cancellation window that matches how your carriers operate.

What are the common mistakes and red flags that lead to disputes?

Most disputes happen because the parties can’t agree on what was promised (appointment, free time, unloading responsibility) or what actually happened (timestamps, receipts).

Common mistakes (and why they matter):

- Treating accessorials as “rare” instead of building them into the operating plan

- Missing or vague appointment notes (no window, no cutoff, no facility contact)

- Not confirming lumper policy and payment method in advance

- No process for capturing check-in/check-out times the moment delays happen

- Trying to dispute without proof (or without a consistent approval workflow)

Red flags that predict accessorial risk:

- “FCFS only” at high-volume receivers

- Ambiguous readiness statements (“should be ready soon”)

- Loads with mixed SKUs, poor labels, or unstable pallet builds

- Facilities that regularly require third-party unloading labor

How should you review an invoice when an accessorial appears?

A simple audit workflow prevents overpaying and reduces the time your team spends on back-and-forth.

5-step accessorial audit workflow:

- Match the fee to the rate confirmation / tender notes (what was agreed)

- Validate the trigger (what happened) using timestamps, notes, or receipts

- Confirm approval policy (who approved, when, and how)

- Confirm pass-through proof for labor fees (receipt + payment record)

- Document outcome: approve, deny with proof, or request more information

If you’re building a repeatable plan to reduce accessorial exposure, it’s often easiest to start by mapping the right service workflow and escalation path for your lane mix.

Frequently Asked Questions

Who usually pays accessorial charges?

It depends on the contract chain. In many setups, the carrier invoices the party that booked the freight (often a broker), and the broker invoices the shipper or customer based on agreed terms. The cleanest approach is to define ownership in writing before tender.

Can accessorial charges be pre-approved instead of “surprises later”?

Yes—many accessorials can be proactive when you know you’ll need special handling (e.g., limited access, extra stops, special equipment). Put the requirements into the quote/tender notes so the cost is visible earlier.

What should a rate confirmation say to reduce disputes?

It should clearly state appointment expectations, cancellation windows, unloading responsibility, and what proof is required for time-based or pass-through charges. The goal is not to “win arguments,” but to remove ambiguity.

What if a receiver can’t take the load today?

You generally have three options: reschedule, route to a controlled transfer step, or rework/stabilize the freight if it’s not deliverable as-is. The best option depends on how time-sensitive the delivery is and what costs you’re trying to avoid.

Next step

If your team is trying to reduce accessorial surprises while keeping freight moving, start by aligning the shipment plan with the right service workflow.