How to Avoid Detention Fees in Freight: A Dock-Side Playbook for Shippers, Receivers, and Brokers

Detention fees show up when a truck is held at a shipper or receiver longer than the “free time” agreed in the rate confirmation or contract. You can’t eliminate every delay, but you can prevent the most common causes with better appointment inputs, dock readiness, and a clean handoff process. This guide focuses on practical prevention steps for day-to-day operations—not ocean demurrage rules or legal disputes.

If your plan involves staging, cross-docking, or exception recovery in the Denver area, start with the service workflow here.

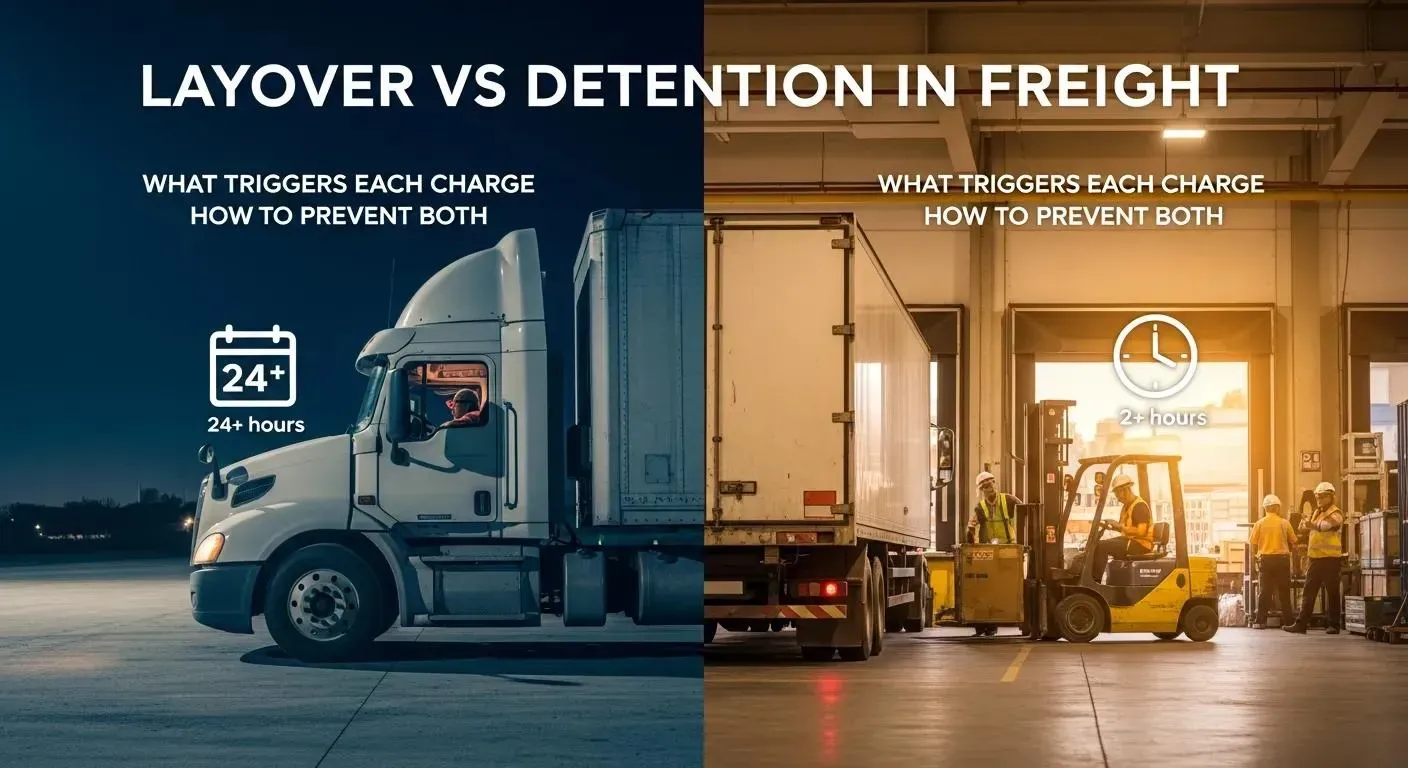

What is detention time, and when do detention fees typically start?

Detention time is the extra time a driver and truck spend waiting at a shipping or receiving facility beyond the agreed loading/unloading window. Fees typically start after the “free time” allowance in your agreement, so the clock is contractual—even if many operations use a two-hour benchmark as a working standard.

Detention matters because long wait times don’t just create cost; they disrupt capacity and scheduling across the network. For background on how detention is studied and discussed in the U.S. trucking context, see FMCSA resources.

What actually causes detention at docks (the predictable failure modes)?

Most detention is caused by a small set of repeatable problems: bad appointment inputs, lack of dock readiness, paperwork mismatches, and unclear scope. When any of those hits, the truck becomes the “buffer” for operational chaos.

Common detention triggers include:

- Appointment time is booked, but the load isn’t staged or the door isn’t available

- Incorrect or missing PO/BOL references (receiver can’t match freight to an inbound record)

- Mixed freight with no destination plan (sorting becomes unplanned labor)

- Live-load expectations without adequate labor/equipment at that time window

- Last-minute changes (dock instructions, trailer type needs, or unloading rules)

Which prevention tactic fits your situation? (decision table)

| Situation | Best prevention move | Why it works | What to confirm before the truck arrives |

|---|---|---|---|

| Live load/unload at a busy dock | Pre-stage the freight + confirm door schedule | Door time is the scarce resource | Door assignment, labor coverage, equipment readiness |

| Receiver requires strict PO/BOL matching | Send a dock packet with correct references | Paperwork mismatches cause the longest dead waits | PO numbers, BOL number, delivery instructions, contact |

| Mixed SKUs / multiple stops | Provide an outbound grouping plan (or label plan) | Sorting during unload adds touches and time | How freight should be separated + label format |

| Unstable pallets / likely exceptions | Define an exception path (rewrap/restack/repalletize) | Prevents open-ended figure-it-out labor | Who approves add-ons + what scope is allowed |

| Tight appointment windows | Use drop trailer or cross-dock transfer when possible | Converts waiting into scheduled handling | Whether drop is accepted; cross-dock timing |

If the best way to reduce detention is to switch from “waiting at the dock” to a planned transfer, cross-docking can be the cleanest option.

Checklist: what to do before pickup or delivery to prevent detention

Use this checklist as your standard pre-appointment routine.

- Confirm the free time allowance and what starts/stops the clock (appointment time vs arrival check-in vs door time)

- Confirm dock hours and any cut-off rules (e.g., last check-in time)

- Confirm the appointment reference requirements (POs, BOL/PRO, order numbers)

- Verify the trailer type and any special needs (liftgate, pallet jack, floor-load vs palletized)

- Confirm whether it’s live load/unload or drop & hook

- Confirm freight readiness (staged, wrapped, labeled, and count-verified)

- Send a single “dock packet” to all parties (dispatcher + shipper/receiver contacts)

- Identify the on-site decision maker who can approve changes quickly

Checklist: what to do when the driver arrives (to keep the clock from drifting)

Detention escalates when arrival is treated as the start of a problem instead of the start of a process.

- Ensure the driver has the correct check-in instructions and location

- Capture a clear arrival time and check-in confirmation (email/text or system timestamp)

- Assign a door (or update the ETA for door assignment) within a defined window

- If freight isn’t ready, communicate a realistic “ready time” immediately

- If paperwork is missing, request exactly what is needed (avoid vague “we can’t take it” messages)

- If scope changes (sorting/verification), get approval before work expands

Two mini-scenarios: how detention happens (and how you prevent it)

Scenario 1: “No PO on the paperwork” turns into a four-hour wait

A driver arrives on time, but the delivery receipt and BOL don’t include the receiver’s required PO reference. The receiving team can’t match the freight to an inbound record, so the truck sits while emails are exchanged.

What prevents it: send a dock packet that includes the correct PO references and a backup contact who can confirm the receiving record quickly.

Scenario 2: A live unload becomes “surprise sorting”

A load arrives with mixed SKUs for multiple internal departments. The receiver expected a single drop, but now staff must separate cartons and rebuild pallets. That turns a simple unload into a labor project.

What prevents it: clarify whether the job is “transfer only” or “transfer + sorting,” and provide a grouping plan (labels or pallet maps) before the truck arrives.

Common mistakes and red flags that lead to detention fees

Most detention fees are the result of preventable ambiguity.

Common mistakes:

- Booking an appointment without verifying freight readiness and dock capacity

- Assuming “two free hours” applies when the contract says something different

- Missing or inconsistent references (PO/BOL/PRO) that the receiver requires

- Treating sorting/verification as “minor” without defining scope and approval

- No single person empowered to make a quick decision when plans change

Red flags that predict detention today:

- The load is not staged, wrapped, or counted by the time the truck is en route

- The receiver has strict inbound rules but the shipper/broker can’t provide required references

- Mixed freight with unclear labels or uncertain destination plan

- Dock congestion + no fallback plan (drop, re-appointment, cross-dock)

Prevention upgrades that reduce detention over time (without new software)

You don’t need a perfect system to make detention rarer—you need repeatable habits.

Practical upgrades:

- Track dwell time by facility, day-of-week, and time window (to book smarter)

- Standardize the dock packet format (one page, same fields every time)

- Use photo proof for “freight ready” (staged pallets + labels) on live loads

- Build an “exception playbook” for unstable pallets and mismatched paperwork

If unstable pallets are a frequent reason for dock delays, a defined rework path helps keep exceptions from becoming open-ended waiting.

Frequently Asked Questions

Is detention the same as demurrage?

No. Detention in trucking typically refers to excessive waiting time for loading/unloading at a shipper or receiver. Demurrage is commonly used for time-based charges related to equipment/container use at terminals or ports.

Does detention always start after two hours?

Not always. Two hours is often used as a working benchmark, but your agreement controls: check the free time allowance and how time is measured (appointment time vs check-in vs door time).

What’s the fastest way to avoid detention when a receiver can’t take a delivery?

Convert the problem from “waiting” to “planned handling”: reschedule quickly, use drop options if allowed, or route the freight to a cross-dock or short-term staging plan so the linehaul truck can keep moving.

Next step

If you want to reduce detention exposure by building a repeatable plan for transfers, staging, and exception recovery, start with the service workflow here:

Services