OS&D Documentation Checklist: What to Record for Overage, Shortage, or Damage (So Cost Recovery Doesn’t Stall)

OS&D (overage, shortage, and damage) is the industry shorthand for freight exceptions where what arrived doesn’t match what the paperwork says—or it arrived in unusable condition. This guide focuses on the fastest, most defensible documentation steps to take at the dock and right after delivery, so you can protect recovery options and reduce avoidable losses.

For your broader service workflow (staging, cross-docking, and recovery support), start here. Services

What does OS&D mean in freight, and what counts as an “exception”?

OS&D means overage, shortage, and damage—three common exceptions that happen at delivery or receiving. An “exception” is any mismatch between the Bill of Lading (BOL) and what you actually received, or any condition issue that affects sellability.

In practice:

- Overage: you received more units than the BOL shows.

- Shortage: you received fewer units than the BOL shows.

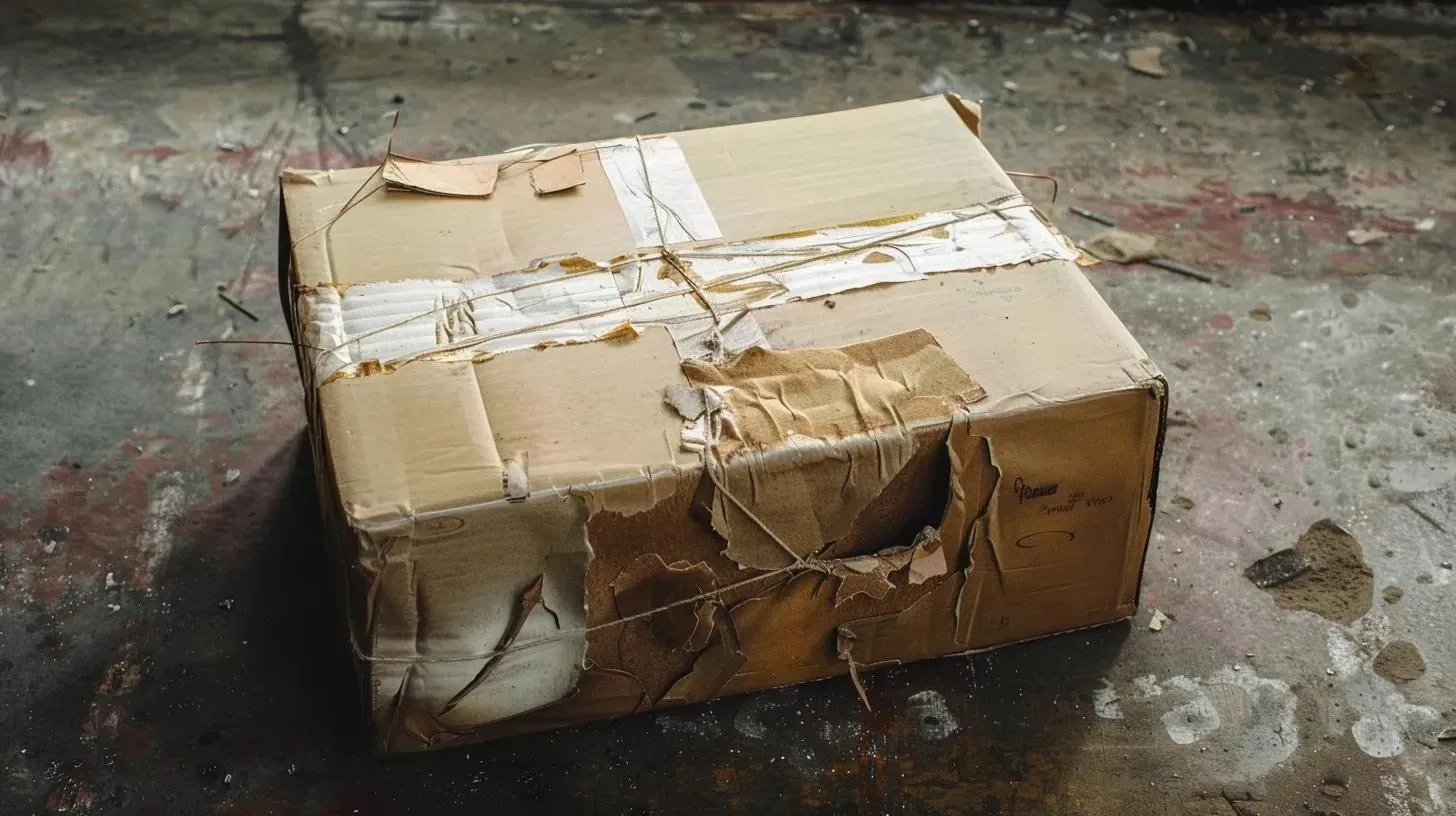

- Damage: freight arrived visibly damaged—or damage is discovered later (concealed damage).

A quick glossary reference for

freight terms is useful for training teams and keeping notes consistent.

What should you document before you sign the POD (delivery receipt)?

Before signing, document what you can prove at the door: counts, visible condition, and packaging clues. If you sign “clean” when there’s a discrepancy, you don’t lose every option—but you often make recovery harder because the record doesn’t reflect what happened.

Here’s the core rule: be specific. “Damaged” is weaker than “2 cartons crushed, pallet leaning, shrink wrap torn, corner impact.”

Decision table: what to document for each OS&D type

| OS&D type | What to write on the POD (examples) | Photos to take (minimum) | Who to notify first | What to keep/preserve |

|---|---|---|---|---|

| Overage | Overage: received 1 extra pallet / 6 extra cases (PO ___). Held for disposition. | Full pallet plus labels and PO marks | Shipper plus broker or dispatcher | Extra goods segregated and clearly labeled |

| Shortage | Short: BOL shows 10 pallets, received 9. Seal intact or broken (note). | Trailer interior, seal, dock area, pallet labels | Shipper plus carrier or broker | All paperwork plus seal evidence |

| Visible damage | 3 cases crushed; pallet corner impact; wrap torn; possible internal damage. | Damaged goods plus all packaging and labels | Carrier or broker plus shipper | Damaged goods and packaging until disposition |

| Concealed damage | If not visible at delivery: note packaging anomalies like carton re-taped, wet, or holes | Packaging anomalies at delivery; more photos when opened | Notify promptly once discovered | Keep packaging plus product and open/close photos |

Helpful reference for general “document the damage” principles (government guidance).

What should you document right after delivery if you discover concealed damage or a shortage?

If damage or shortage is discovered after the driver has left, your best move is to create a time-stamped, organized exception file immediately. The goal is to show a clear chain of evidence: what you expected, what arrived, and what you observed.

Your “right after” evidence kit should include:

- Photos of the product and all packaging (including pallet deck, corners, wrap pattern, labels)

- A short written description with quantities, SKU/lot, and what’s unusable

- The receiving timeline (when unloaded, when discovered, who discovered it)

- Notes about seal condition and any re-taping/wet/holes/crush points

Which documents do carriers usually request for an OS&D claim file?

Carriers and claims teams typically request a small set of standard documents so they can investigate and validate value. In U.S. motor carriage contexts, supporting documents often include the bill of lading, evidence of freight charges, and value documentation such as an invoice when needed for investigation.

In practical operations, your OS&D documentation packet commonly includes:

- Bill of Lading (BOL)

- Proof of Delivery (POD) / delivery receipt (with exception notes if any)

- Packing list / count sheet

- Commercial invoice (or other proof of value)

- Photos (damage + packaging + labels)

- Inspection report (if completed) or request/waiver notes

- Email/text trail of notifications (who you told, when)

What’s the fastest checklist your receiving team can follow (dock-side + same-day)?

The best OS&D outcomes come from repeatable behavior at the dock. Use this as your standard operating checklist.

Dock-side OS&D checklist (before signing):

- Verify pallet/carton count against BOL and packing list

- Inspect pallet stability (leaning, shifted stack, broken deck boards)

- Inspect packaging (holes, crush, torn wrap, re-tape, wet marks)

- Photograph: full load + closeups of labels + any anomalies

- Note exceptions on POD with specific language (what, how many, where)

- Record seal number and seal condition (intact/broken/mismatch)

Same-day OS&D checklist (after unloading):

- Separate questionable product and label it “HOLD – OS&D”

- Take “unpacked” photos showing internal damage (if applicable)

- Save all packaging materials (don’t discard wrap/cartons/pallets)

- Create a single OS&D case folder and drop all documents into it

- Notify the shipper/broker and carrier contacts with a short summary + photos

How do you preserve evidence without creating extra storage or disposal cost?

Preserve evidence by holding only what’s necessary and documenting clearly what you did with the product. The goal is to avoid discarding the very proof you’ll need later.

A practical approach is:

- Segregate OS&D freight in a clearly marked location

- Keep the packaging and pallets associated with the damage

- If you must dispose of anything for safety/sanitation reasons, document why and keep photos and approvals

If the freight is unstable or needs to be made safe to handle, rework/stabilization can limit compounding loss while you keep your documentation clean.

What should an OS&D case file look like (so it’s easy to approve or dispute costs)?

A simple, consistent file structure reduces time wasted later.

OS&D case folder structure (recommended):

- 01_BOL_POD

- 02_Packing_List_Counts

- 03_Photos_At_Delivery

- 04_Photos_After_Unpack

- 05_Invoice_Value_Docs

- 06_Inspection_Reports

- 07_Communications_Timeline

One-paragraph “case summary” template (paste into email):

- PRO number / BOL number:

- Delivery date/time:

- Exception type (O/S/D):

- Quantity affected:

- Condition notes (specific):

- Photos attached (what they show):

- Current status (held, segregated, reworked, disposed with approval):

Mini-scenarios: how documentation changes outcomes (two examples)

Scenario 1: Shortage with an intact seal

A receiver expects 10 pallets but counts 9. The seal is intact and matches the paperwork. The team notes “Short: BOL 10 pallets, received 9; seal intact and matching; trailer clean” on the POD, photographs the seal and trailer interior, and creates a case folder that includes the packing list and receiving count sheet.

Why this helps: the record shows the discrepancy was identified immediately and ties the shortage to traceable shipment identifiers.

Scenario 2: Concealed damage after a clean POD

A shipment arrives with a carton that looks re-taped and slightly crushed, but the team is rushed and signs clean. During put-away, they open the carton and find product damage. They immediately photograph the carton, internal packing, damaged items, and create a time-stamped summary of when the damage was discovered.

Why this helps: while a clean POD can complicate recovery, quick, organized evidence (especially packaging-focused photos) can still support investigation and reduce “he said / she said” disputes.

Common mistakes and red flags that delay recovery or increase total loss

Most OS&D failures aren’t because the exception happened—they’re because the evidence trail is weak.

Common mistakes:

- Signing the POD without inspecting counts or obvious packaging anomalies

- Writing vague notes (“damaged,” “short”) without quantities or descriptions

- Throwing away packaging/pallets before taking photos

- Spreading evidence across texts/emails with no single case folder

- Waiting too long to notify the relevant contacts after discovery

Red flags that predict disputes:

- Clean POD with no photos, followed by a “later discovered” claim

- No proof of value (invoice or destination value documentation)

- No receiving count sheet or mismatch between count sheets and POD notes

Next step

If you want to reduce OS&D disruption and keep freight moving when exceptions happen, align your exception workflow with the right

service path (including stabilization and recovery options)